what is epdm foam?

What is EPDM Foam?

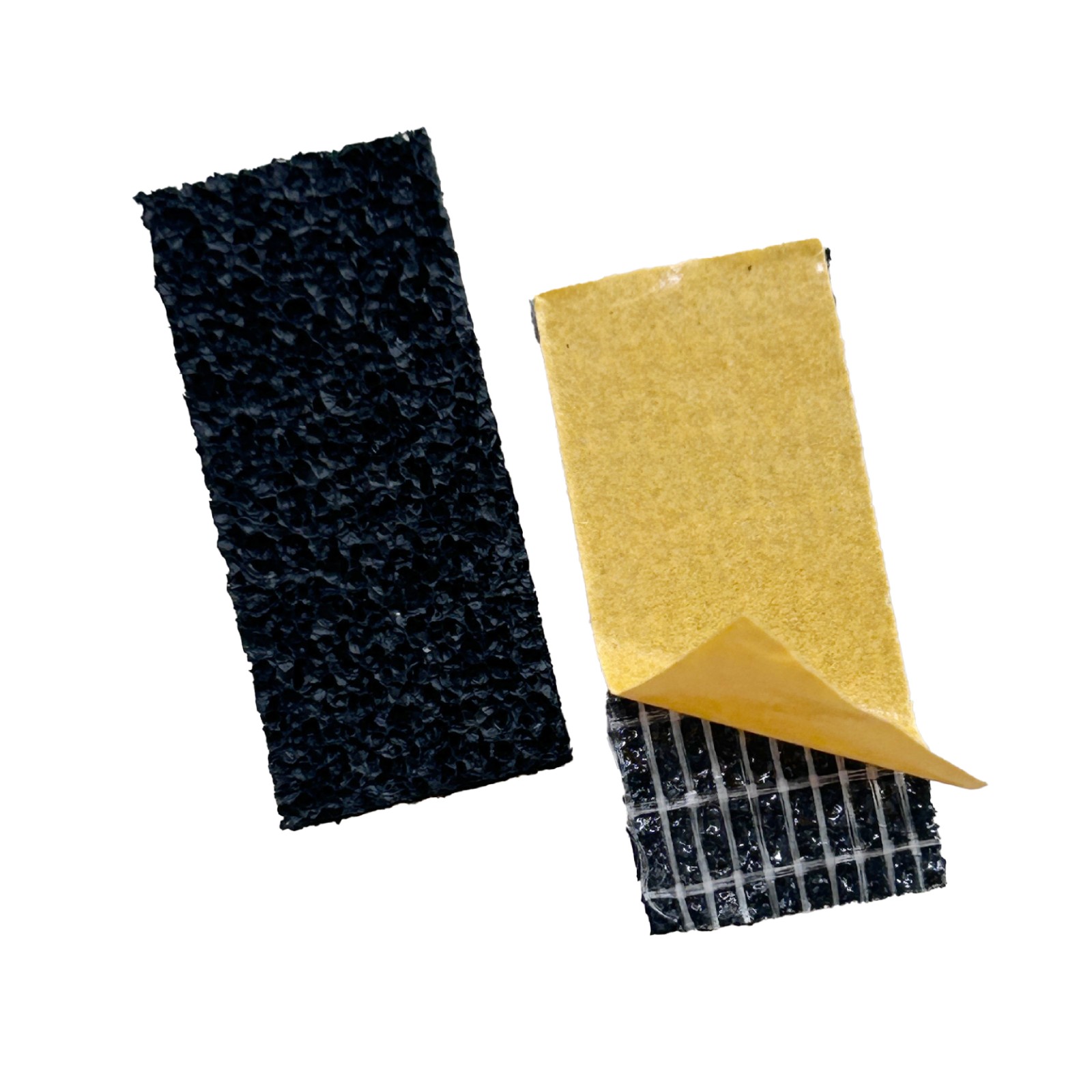

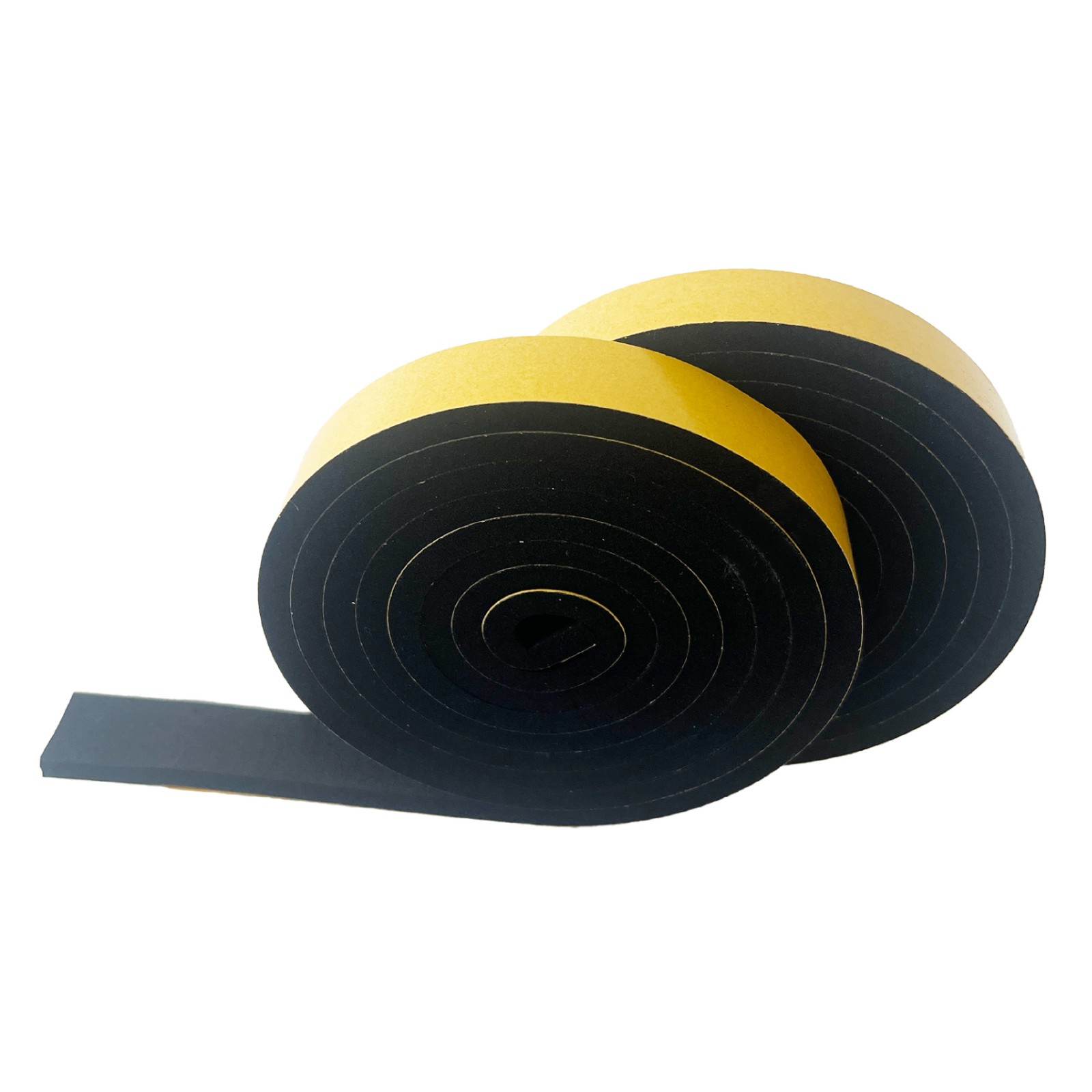

EPDM foam is lighter and more porous than solid EPDM; however, it is still a resilient and long-lasting material that is ideal for industrial applications. A foam EPDM part excels in highly compressive applications as its porous structure is able to offer a tighter seal. EPDM manufacturers are able to dictate the density of a cellular EPDM sheet by applying pressure to the material to create smaller air pockets and reducing pressure for larger air pockets. Although they are porous in nature, EPDM sponge still retains excellent resistance to harsh UV rays, ozone, and oxygen. Although they both retain the same environmental resistance properties, an open and closed cell EPDM part are each generally used for different applications due to their difference in density.

|  |  |  |

A foam EPDM sheet, both open and closed cell, are often used for applications that require a tighter seal due to its high compressibility. Unlike solid EPDM, EPDM foam is a light and airy material that is created when EPDM manufacturers introduce gases into the material during its production process. Closed cell EPDM foam is a highly moisture resistant material with an absorption level of less than 5%, due to the smaller air pockets that make up its structure, whereas open cell EPDM is highly absorbent. EPDM sponge, like its solid counterpart, is resistant to damaging environmental factors and retain a wide operating temperature range, allowing a foam EPDM part to work well in applications involving abrasive temperatures. Overall, EPDM foam, despite their light and airy structure, is a long-lasting industrial material that is able to withstand highly compressive applications in outdoor and indoor industrial settings.

- Prev: Acoustic Rating Systems

- Next: what is cork

CN

CN ENGLISH

ENGLISH